With overwhelming merits in higher density, more regular shape, easily classifying and assorting, superior grinding efficiency and competitive price prior to natural cobble stones and conventional grinding media, ball mill used high alumina ceramic balls are excellent for grinding processing of many industries. As grinding media, it is widely used in ceramic industry, cement industry, paint industry, color industry, chemical industry, pharmaceutical industry, coating industry and mining industry.

The high alumina ceramic grinding media has the following properties:

♦ High hardness second only to Diamond

♦ Lower wear loss

♦ Good normalization

♦ Good corrosion resistance

♦ Higher grinding efficiency

♦ Contamination-free

♦ Longer service life

Technical Index of high alumina ceramic balls:

|

Al2O3 Content |

≥92% |

| SiO2 |

≤7% |

| CaO + MgO+ Fe2O3+Others |

2% |

| Bulk Density |

≥3.62g/cm3 |

| Water Absorption |

≤0.01% |

| Hardness |

9 Mohs |

| Self Wear Rate |

≤0.01% (24h) |

|

Dia.(mm) |

Φ60-80 |

Φ50 |

Φ40 |

Φ30 |

Φ25 |

Φ20 |

Φ10-15 |

Φ2-10 |

| Tolerance (mm) |

±2 |

±2 |

±2 |

±1.5 |

±1.5 |

±1.5 |

±1 |

±0.3 |

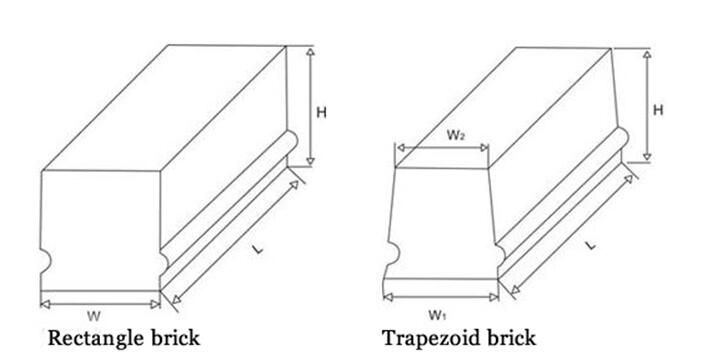

High wear resistance 92% Alumina Ceramic Lining Bricks for Ball Mill Liner are sintered on high temperature of more than 1530℃, with high-purity ultra-fine alumina powder as raw material according to optimized formulation design. They are usually installed upon the wear areas of some material conveying equipment, coal preparation equipment and so on to be used as the material contact surface to bear the following abrasion and impact.

Alumina lining brick is ideal for ball mill lining, it has high strength, high resistance to wear and tear, high resistance to corrosion. Alumina brick is ideal partner of alumina grinding ball.

Guidance for Using:

| Mill Tonnage |

<0.3Ton |

0.5Ton |

1-1.5Ton |

2.5-3Ton |

5-25Ton |

30-40Ton |

| Rectangle: Trapezoid |

0:1 |

1:10 |

1:1 |

2:1 |

3:1 |

5:1 |

Description: Calculation of alumina liner installed in ball mill

1. The number of alumina liners installed on two end faces:

(1)Quantity of rectangle liners on the end face: S=3.14×R2÷ (L1×W)

Remarks:

S: the number of rectangle bricks on the end face of ball mill.

R: the semi-diameter of the end wall of ball mill.

W: the width of lining bricks L1: the length of lining bricks.

(2) Quantity of half-rectangle bricks on the end face: S1=D÷W

Remarks:

S1: the number of half-rectangle bricks on the end face.

D: the diameter of the end face.

W: the width of alumina lining brick

2. The quantity of alumina bricks installed on the ball mill:

(1) The total of liners: S2=P1×P2 P1=3.14×D÷W, P2= (L-2H) ÷ L1

Remarks:

S2: The total number of rectangle bricks and trapezoidal bricks on the cylinder.

P1: the rows of bricks on the cylinder. P2: number of bricks in each row.

D: the diameter of the end face, H: the thickness of liner, L: the length of Ball mill.

W: the width of alumina liner L1: the length of alumina liner.

Remarks:

S2: The total number of rectangle bricks and trapezoidal bricks comes from the tonnage of Ball mill in the following table. Base on the proportion in the table calculating the quantity of rectangle liner S21 and trapezoidal liner S22 according to the proportion in the table.

(2)The total No. alumina liner:

Rectangle Liner=2S+ S21 Trapezoidal Liner = S22

Half-rectangle Brick =2S1+ S31 Half-trapezoidal Brick= S32

Flake Brick=P2

Sizes of 92% & 95% AL2O3 Alumina Lining Brick (mm)

| |

Rectangle brick |

Trapezoid brick |

Flake brick |

Half-Rectangle brick |

Half-Trapezoid brick |

| Length |

150 |

150 |

150 |

75 |

75 |

| Width |

50 |

50/45 |

25 |

50 |

50/45 |

| Height |

90/80/70/60/

50/40mm |

90/80/70/60/

50/40mm |

90/80/70/60/

50/40mm |

90/80/70/60/

50/40mm |

90/80/70/60/

50/40mm |

Being the wear-resistant liner for the ball mill, alumina lining brick is the best choice to increase the grinding efficiency and reduce the grinding cost. Currently, alumina lining brick is being widely used in ceramic, cement, paint, pigment, chemical, pharmacy and coatings industries. |